Quick replacement, perfectly overhauled

Your contact

All problems solved in-house

With our 12 component shops, we are prepared for all your needs. All components can be overhauled. Whilst our specialists meticulously focus on your component in need of repair, we provide you with an immediate low-cost replacement.

Interior shop

In our interior shop, our technicians work on the interior of the aircraft. They repair and recondition all parts of your aircraft interior: e.g. galleys, toilets, walls, baggage compartments, cockpit casing or cargo holds. Our interior specialists are happy to cater all your specific needs and design concepts. With skilled specialists, we laminate and refinish, glue and redecorate, weld thermoplastics, plot, remix paint, remove dents, with spot repairs and refine surfaces using various airbrush procedures.

Boot shop

Our surface specialists work in the boot shop. Their daily work includes checking the relevant aircraft components and attending to fast repairs or replacing leading edges, air intakes and duct assys.

In case of repair, they take off the discarded boots, remove the old adhesive and mend the damage.. The new boot is then fitted and the components finished and then sealed. Once the repair is completed, a “release to service” report is filled out and the component is then sent to the warehouse – or to you directly.

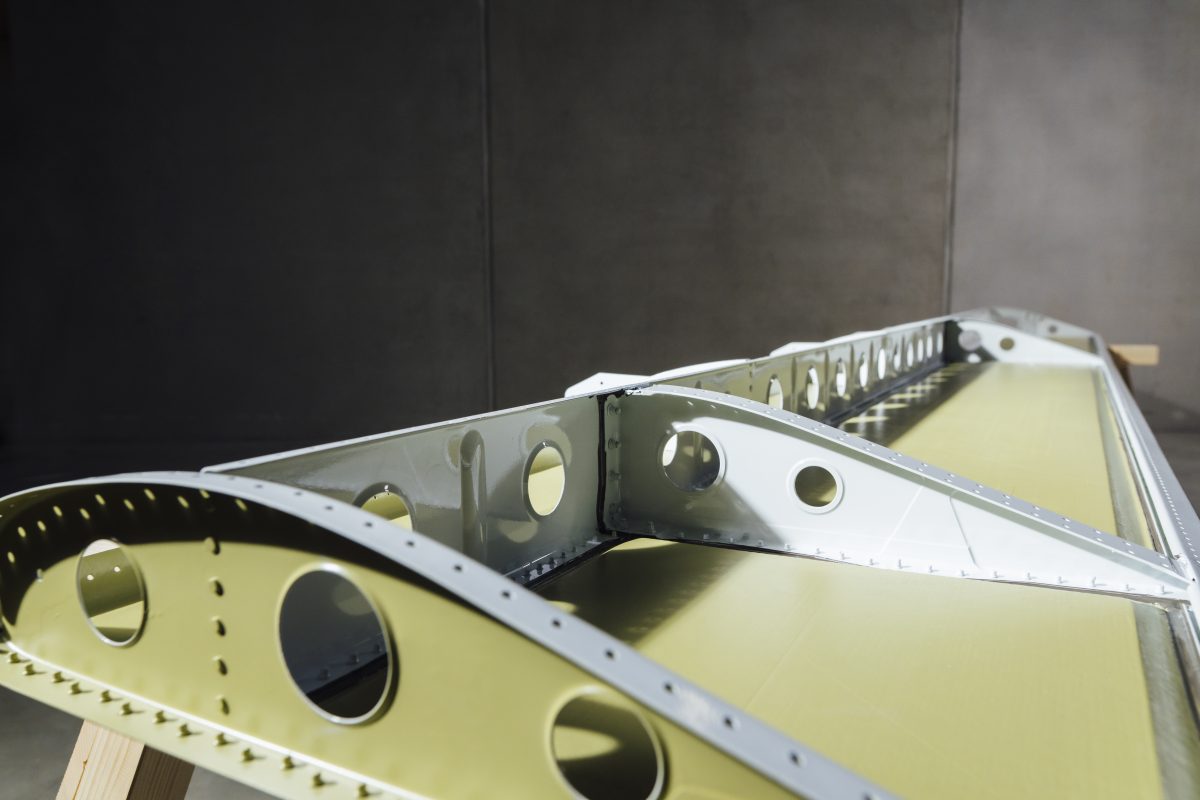

Flight Control Shop

In our flight control shop, we recondition and repair landing flaps, ailerons, elevators and rudders. Naturally in accordance with all the manufacturers’ specifications.

Our specialists overhaul rejected parts quickly and precisely. These parts are open, inspected, fixed, overhauled, inpart renewed, reassembled and then sent back to you.

Our flight control shop manages a huge annual output of approximately 50-60 newly certified flight control repairs. This is due to the fact that we have highly trained specialists in their field. They use high-precision tools and work rigorously and routinely to make sure your downtime is as quick as possible.

Repaired in accordance with the manufacturer’s instructions and international and national regulations.

Composite Shop

Our composite shop technicians deal with your aircraft’s composite fiber structure. They scrutinize all linings, flight controls and floor plates. They microscopically examine small cracks in the composite fiber components as well as inspect deep and extensive structural damages. They can repair these composite materials and metal structures with state-of-the-art vacuum heat bonding technology, returning them to full airworthiness.

It is important for you to know that we have all the required special tools at our fingertips in the composite shop and can therefore reliably guarantee short downtimes and ensure long-lasting flight operation.

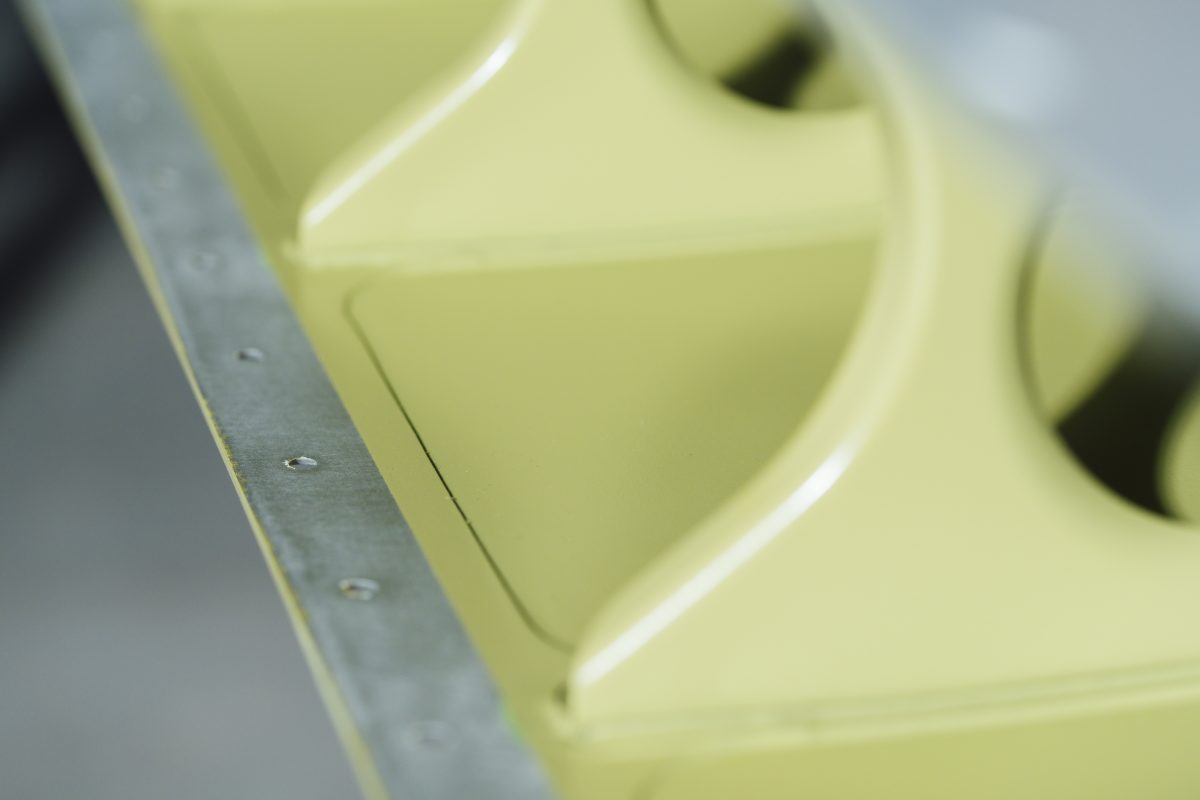

Paint Shop

Our painters do everything possible to fully protect the shell of your aircraft. They ensure that the finish as well as your corporate colors gleam in the sky. We have a state-of-the-art finishing system for structural components. We also do partial painting of the fuselage, wings, horizontal and vertical tails. We have a state-of-the-art finishing system for structural components. We also do partial painting of the fuselage, wings, horizontal and vertical tails.

The big advantage for you is that we are able to carry out all paintwork directly in-house. This means that all jobs arising from the other shops – such as preparatory work for painting and painting leading edges for the boot shop – can be directly completed inhouse, without any outside detours.

Door Shop

Our door shop experts handle the repairs and reconditioning of all aircraft doors. This includes landing gear doors, passenger doors or freight room doors. After precise examination of structural damages, components are either rectified or replaced when necessary.

Our technicians also modify and repair nav light covers, landing light covers and tailcone end caps. They sand and polish tarnished and milky surfaces for full luminosity. The door shop also stocks reconditioned doors that are ready for installation.

Precision Shop

Our precision engineers work in the precision shop. They rectify problems directly on your aircraft as well as repair or condition aircraft components. They turn, mill, drill and weld and, if needed, they also produce made-to-measure parts in accordance with the manufacturers’ instructions.

For example, complex vacuum welding work is also made on air inlet and air outlet parts or on ATR components consisting of resilient titanium or so-called Inconel super alloys. Once these components can then be built into your aircraft directly in our hangar. As all requirements can be handled in-house downtimes are short and costs are lower.

Saddlery

Here you will find our aircraft interior fitters, who are also trained saddlers. They cut, weave or handloom carpets. They also produce all types of aircraft covers – for example handmade propeller covers. One of their major tasks include the maintenance, inspection and reconditioning of pilot seats.

A sewing machine specifically manufactured for our saddlery enables precise work down to the millimeter as well as the production of exceptional custom-made products – for your business jet for example. Take advantage of the wide-ranging experiences of our employees, which ultimately results in lower costs for you.

Wheel Shop

In the Wheel Shop, we provide reliable maintenance and repair services for your aircraft wheels and brakes. Our team thoroughly inspects all components for wear and damage. If necessary, we clean the parts, replace bearings or brake pads, and expertly mount the wheels. We then balance them with precision. With quick turnaround times, we ensure optimal safety and minimize downtime for your fleet.